Specialty Edge Finishing

If you the edges are visible and you desire a more decorative finish for your glass, we offer several options:

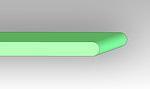

Pencil Edge: This type of edgework results in an edge that is slightly rounded. Pencil Grind edgework has a frosty, matte, or satin finish. Pencil Polish edgework provides a glossy, shiny finish; perfect for a style when you are wanting to create an extra pop!

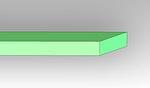

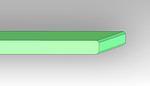

Flat Edge: This type of edgework results in an edge that is Flat with small chamfers on the corners. Flat Grind edgework has a matte, frosty or satin finish. Flat Polish edgework provides a shiny or glossy finish.

Bevel Edge: This type of edgework adds a sense of depth on the glass. This is often used for an ornate application. Bevel Edges have a shiny or glossy finish.

We possess state-of-the-art machinery, handled by our expert craftsmen, to fulfill almost any custom edgework request!

Seamed Edge

Seamed

Pencil Edge

Pencil Grind

Pencil Polish

Flat Edge

Flat Grind

Flat Polish

Bevel Edge

Bevel

One Day Glass can put the perfect edge on your piece of glass. Whether you need standard or specialty edgework on your glass, you can be assured that each edge will be precision machined on our state of the art edging machine. Just let us know if your project requires a special edge and we’ll give it a great, customized look with our quality edgework. If not, we’ll still make sure you always get pieces with edges that are sanded and safe to handle.

One Day Glass can put the perfect edge on your piece of glass. Whether you need standard or specialty edgework on your glass, you can be assured that each edge will be precision machined on our state of the art edging machine. Just let us know if your project requires a special edge and we’ll give it a great, customized look with our quality edgework. If not, we’ll still make sure you always get pieces with edges that are sanded and safe to handle.

Specialty Edgework removes any uneven appearance on the edge of the glass after it has been cut. Another benefit of specialty edgework is the enhanced appearance of the glass. Our edges are not sharp, this is true whether you choose standard edgework or specialized edgework. Specialized edgework gives the glass a great appearance.

Standard edgework is our standard finish and is included at no extra charge on all pieces. We call this the seamed edge. This is perfect for items that will be installed so that the edges of the glass will not be seen, these edges are sanded smooth so the glass is safe to handle but it is not necessarily decorative. Our standard edgework will follow industry standard tolerances.

Specialty Edgework options can be added to many pieces or shapes for an extra charge. Use the Instant Online Quote feature above to quickly estimate the cost for your specific project.

Glass Tints Available by Type & Thickness:

- Tempered Glass

- 1/8" Thickness

Clear

Clear Solex

Solex Bronze

Bronze Light Gray

Light Gray Dark Gray

Dark Gray Satin Etch

Satin Etch P-516

P-516 Mistlite

Mistlite Low-E

Low-E Frosted GlueChip

Frosted GlueChip

- 5/32" Thickness

Clear

Clear Solar Cool Bronze

Solar Cool Bronze Narrow Reed

Narrow Reed Delta Frost

Delta Frost Seedy Reamy

Seedy Reamy Pattern 42

Pattern 42 Kasumi

Kasumi

- 3/16" Thickness

Clear

Clear Solex

Solex Bronze

Bronze Light Gray

Light Gray P-516

P-516 Solar Cool Bronze

Solar Cool Bronze Rain

Rain

- 1/4" Thickness

Clear

Clear Solex

Solex Bronze

Bronze Light Gray

Light Gray Dark Gray

Dark Gray Solar Cool Bronze

Solar Cool Bronze Low Iron

Low Iron Satin Etch

Satin Etch Mirrorpane

Mirrorpane

- 3/8" Thickness

Clear

Clear Shower Guard Clear

Shower Guard Clear Gray

Gray Low Iron

Low Iron Satin Etch

Satin Etch Rain

Rain Bronze

Bronze

- 1/2" Thickness

Clear

Clear Shower Guard Clear

Shower Guard Clear Low Iron

Low Iron Satin Etch

Satin Etch

- 3/4" Thickness

Clear

Clear

- Tempered Laminate

- 1/4" Thickness

Clear / Clear

Clear / Clear Solex / Clear

Solex / Clear Bronze / Clear

Bronze / Clear Light Gray / Clear

Light Gray / Clear Dark Gray / Clear

Dark Gray / Clear Opaque White

Opaque White

- 3/8" Thickness

Clear / Clear

Clear / Clear Solex / Clear

Solex / Clear Bronze / Clear

Bronze / Clear Light Gray / Clear

Light Gray / Clear Opaque White

Opaque White

- 1/2" Thickness

Clear / Clear

Clear / Clear Solex / Clear

Solex / Clear Bronze / Clear

Bronze / Clear Light Gray / Clear

Light Gray / Clear Dark Gray / Clear

Dark Gray / Clear Opaque White

Opaque White Low Iron

Low Iron

- 5/8" Thickness

Clear / Clear

Clear / Clear Solex / Clear

Solex / Clear Bronze / Clear

Bronze / Clear Light Gray / Clear

Light Gray / Clear Dark Gray / Clear

Dark Gray / Clear Opaque White

Opaque White Low Iron

Low Iron

- 3/4" Thickness

Clear / Clear

Clear / Clear Gray / Clear

Gray / Clear Opaque White

Opaque White Low Iron

Low Iron

- 7/8" Thickness

Clear / Clear

Clear / Clear Gray / Clear

Gray / Clear Opaque White

Opaque White Low Iron

Low Iron

- 1" Thickness

Clear / Clear

Clear / Clear Opaque White

Opaque White Low Iron

Low Iron

- Annealed Glass

- 1/8" Thickness

Clear

Clear Solex

Solex Bronze

Bronze Light Gray

Light Gray Dark Gray

Dark Gray Satin Etch

Satin Etch P-516

P-516 Mistlite

Mistlite Seedy

Seedy Frosted GlueChip

Frosted GlueChip

- 5/32" Thickness

Clear

Clear Solar Cool Bronze

Solar Cool Bronze Narrow Reed

Narrow Reed Delta Frost

Delta Frost Seedy Reamy

Seedy Reamy Pattern 42

Pattern 42 Kasumi

Kasumi

- 3/16" Thickness

Clear

Clear Solex

Solex Bronze

Bronze Light Gray

Light Gray P-516

P-516 Solar Cool Bronze

Solar Cool Bronze Rain

Rain

- 1/4" Thickness

Clear

Clear Solex

Solex Bronze

Bronze Light Gray

Light Gray Dark Gray

Dark Gray Solar Cool Bronze

Solar Cool Bronze Low Iron

Low Iron Satin Etch

Satin Etch Mirrorpane

Mirrorpane Diamond Wire

Diamond Wire

- 3/8" Thickness

Clear

Clear Gray

Gray Low Iron

Low Iron Satin Etch

Satin Etch Rain

Rain Bronze

Bronze

- 1/2" Thickness

Clear

Clear Low Iron

Low Iron Satin Etch

Satin Etch

- 3/4" Thickness

Clear

Clear

- Laminate / Safety Glass

- 1/4 Laminate

Clear

Clear Solex

Solex Bronze

Bronze Light Gray

Light Gray Diffused White

Diffused White Diamond Wire

Diamond Wire

- Insulated Unit / Dual Pane

- 1/8" Thickness

Clear / Clear

Clear / Clear Low-E / Clear

Low-E / Clear Solex / Clear

Solex / Clear Light Gray / Clear

Light Gray / Clear Dark Gray / Clear

Dark Gray / Clear Bronze / Clear

Bronze / Clear P516 / Clear

P516 / Clear Satin Etch / Clear

Satin Etch / Clear Bronze / Low-E

Bronze / Low-E P516 / Low-E

P516 / Low-E Light Gray / Low-E

Light Gray / Low-E Frosted GlueChip / Clear

Frosted GlueChip / Clear Solex / Low-E

Solex / Low-E

- 5/32" Thickness

Clear / Clear

Clear / Clear Solar Cool Bronze / Clear

Solar Cool Bronze / Clear Narrow Reed / Clear

Narrow Reed / Clear Low-E / Clear

Low-E / Clear Rain / Clear

Rain / Clear Seedy Reamy / Clear

Seedy Reamy / Clear

- 3/16" Thickness

Clear / Clear

Clear / Clear Solar Cool Bronze / Clear

Solar Cool Bronze / Clear Low-E / Clear

Low-E / Clear Solex / Clear

Solex / Clear Light Gray / Clear

Light Gray / Clear Bronze / Clear

Bronze / Clear P516 / Clear

P516 / Clear Bronze / Low-E

Bronze / Low-E P516 / Low-E

P516 / Low-E Light Gray / Low-E

Light Gray / Low-E Solex / Low-E

Solex / Low-E Rain / Clear

Rain / Clear

- 1/4" Thickness

Clear / Clear

Clear / Clear Low-E / Clear

Low-E / Clear Solex / Clear

Solex / Clear Light Gray / Clear

Light Gray / Clear Dark Gray / Clear

Dark Gray / Clear Bronze / Clear

Bronze / Clear Satin Etch / Clear

Satin Etch / Clear Bronze / Low-E

Bronze / Low-E Light Gray / Low-E

Light Gray / Low-E Solex / Low-E

Solex / Low-E Rain / Clear

Rain / Clear Clear Tempered / Laminate

Clear Tempered / Laminate

Since our glass tints are through the entire thickness of the glass, it is more durable and will not rub off like tinted films will. Glass tints of the same color will appear darker with thicker glass. Look at the color charts by thickness to see how the tint will affect darkness.

At One Day Glass we carry glass in several different tints, which vary according to thickness. And we can cut tinted glass within an industry-leading 1/16th-of-an-inch cutting tolerance, which means we can match your exact specifications. Check out our tint samples and see if tinted glass might be a good fit for your next project.

Custom Edge Finishing FAQS

A flat polished edge is something that you use to complete a finished look suitable for display purposes. This works well for mirrors, retail display cases, and other furniture pieces. You can raise the flat polished edge, also known as a chamfer, where the two angled edges meet. Take note that the flat polished edge achieves a thicker appearance. This is because refined looks are commonly used for 1/4-inch glass or thicker.

You can refine the edges of tempered glass by following these four simple steps:

- First, you have to wear safety goggles to protect yourself from the possibility of flying glass pieces. Also, make sure to wear thick gloves because you will be handling sharp edges.

- Next, you have to lay the glass down on a hard, flat surface. Doing so provides a stable platform where you can work efficiently.

- You may use a whetstone to soften the glass. Do this by running it along the edges of the glass. Make sure not to apply too much pressure, but keep firm and even.

- Lastly, use a damp cloth to clean the edges of your glass.

Rounded edges characterize a double pencil edge compared to flat polished edges. They are desired for their smooth and comfortable feel, especially when people are leaning against the edge of the counter or sitting at a breakfast bar.

A beveled glass mirror can highlight both the mirror and the frame, making it a better option than a plain glass mirror. The glass used in a beveled glass mirror is also thicker, which adds to the mirror’s weight. Compared to plain glass, beveled glass is manufactured using an exact size to fit the mirror. This is why bevel glass is more expensive than other glass types.

All packages are sent insured. Our standard shipping method is FedEx Ground which delivers most domestic shipments within 7 business days but in most cases we can ship as fast as FedEx Next Day Air.

All packages are sent insured. Our standard shipping method is FedEx Ground which delivers most domestic shipments within 7 business days but in most cases we can ship as fast as FedEx Next Day Air.